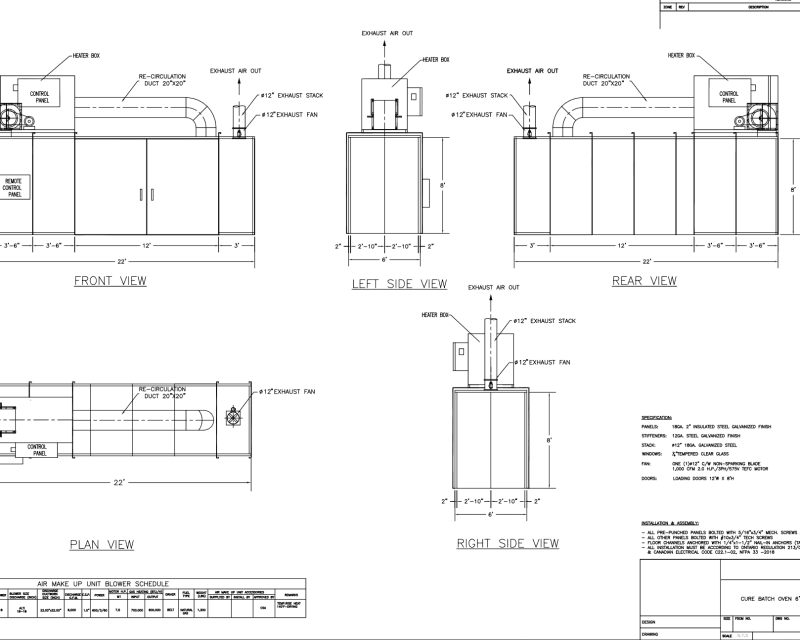

Paint Curing Ovens

Low temperature and High temperature insulated batch style curing ovens.

ADVANTAGES OF SUNKISS-EPI CUSTOM INDUSTRIAL BATCH OVENS:

- Industrial Burner with 40:1 Turn Down Ratio

- Quickly reaches operating temperature

- Wide modulation range

- Low gas consumption

- Reliable, durable, and high efficiency o Meets CSA B149.3 and NFPA 86 standards

- Recirculation Fan

- Robust and high temperatures construction

- Motor with VFD for precise air control

- Enhances heat transfer and improves temperature uniformity in the oven

- Optimization of curing cycles: fusion, thermal transfer, flexibility

- Exhaust Fan

- Designed for continuous hot air exhaust operation

- Motor with VFD for enhanced control of heat loss and purge times

- High capacity for effective and rapid air exhaust

- Air Duct System

- Unique design for precise air handling adjustment

- Easy and flexible balancing

- Customized systems: Mechanically Adjustable Louvered at the Bottom of the Oven or Fixed at the top

- PLC Control via HMI (Touchscreen)

- Intuitive and easy-to-use interface

- Clear visualization of oven status

- Alarm display and storage

- Superior Structure and Insulation

- Solid, self-supporting construction (no insulated panels)

- No thermal bridge between the oven’s interior and exterior walls

- Exterior temperature < 95°F (for 400°F inside)

- Heat loss reduction

- Robust handles with stainless steel plates for easy cleaning

ALL OUR OVENS INCLUDE:

- Customized design and engineering

- Detailed technical drawings

- Stack and system installation

- Complete oven installation

- Start-up and operational testing

- Gas approval according to CSA-B149.3-20

- Electrical approval according to CSA-SPE-1000

- Detailed user manual • Full training

AVAILABLE OPTIONS:

- Hybrid energy consumption (Gas/Electricity)

- Electric heating elements

- Sunkiss® Infrared Emitters

- Cooling system at the end of curing cycle or hot air captation system with door openings

- Conveyor systems

- Advanced programming: Additional curing cycles, Data logging, VPN access, usage time tracking for maintenance management

- Maintenance services

- Essential spare parts in stock